–

–

Product Case Studies

Auto parts

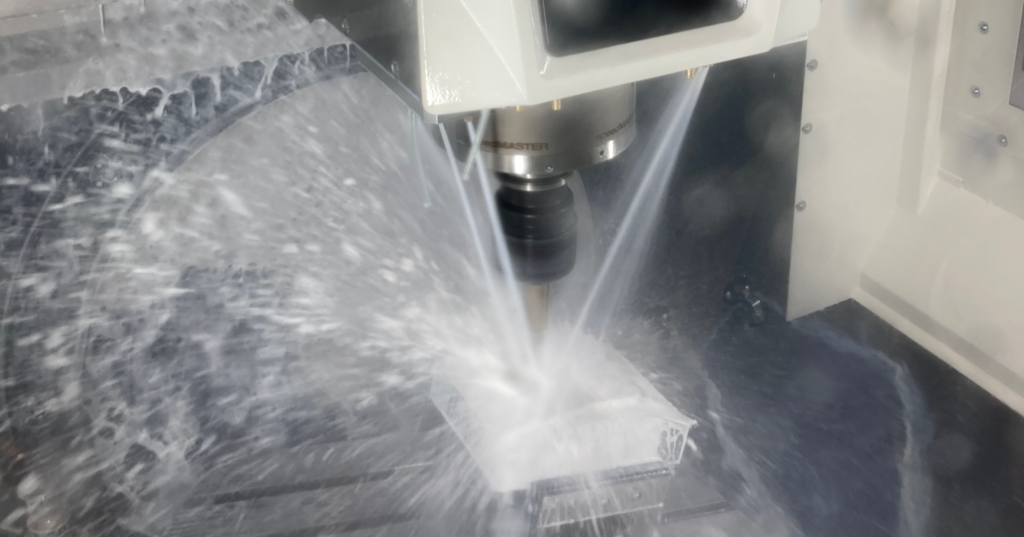

SAKURAI has an extensive record when it comes to processing parts that are central to automobiles, such as transmission cases and engine parts.

Backed by advanced technology, we can provide high-quality functional parts to automobile manufacturers, both domestically and overseas.

In recent years, we have also been contracted to produce cases for drive motors

Industrial machinery/general-purpose parts

SAKURAI processes engine parts for outboard motors and agricultural machinery. In addition to the stable supply of products, we have a dedicated line to handle multi-variety, multi-functional products.

–

–

Prototype/lot production

In the processing of prototypes, with confidentiality at the core of what we do, we maintain a challenge mindset towards the development of new technologies. Providing parts that can withstand extreme environments is proof of our technical capabilities, and we are in constant pursuit of even higher precision.

5-axis control machining center

R0 corner end mill processing

Male and female connector processed to fit pin angle.

Thin ribbed sphere

Each rib is 0.4mm thick and is composed of a combination of pentagons and hexagons.

There is a reverse bank on the protruding part of the pentagonal part,

and it can only be used with 5-axis simultaneous control machining.

The protrusions in between the ribs are attached for protection.

Octo structural sphere

Machined from a single piece of material.

Each sphere has a minimum clearance of 0.5mm

and has a combination of 5 and 6 corners on the exterior.

It is a 32-sided and the inner surface is spherical

–

–

–

Production Record

–

| 1) AT/MT/CVT case processing for automobile powertrains | approx. 12,000 units monthly |

| 2) Machining motor cases for driving automobiles | approx. 4,000 units monthly |

| 3) Cylinder head processing for automobile V6 engines | approx. 6,000 units monthly |

| 4) Other general-purpose engines and outboard engines such as cylinder heads, head covers, etc. | approx. 4,000 units monthly |

| 5) Machining of cylinder heads and blocks for engines of agricultural and construction machinery | approx. 2,000 units monthly |

| 6) Motorcycle cylinder processing | approx. 30,000 units monthly |

Case study of Non-mass production parts

1. Fixed-term on-demand production

Support for customers whose production capacity is overwhelmed by demand, based on contractsranging from around three to twelve months. Examples include

1)Passenger car transmission cases: 16,000 units (8,000 sets) per month under 6-month contracts

2)Cylinder heads for straight-six diesel engines of passenger cars: 100 sets per month over one year

3)Motorcycle cylinder heads: 2,000 units per month over six months

2. Long-term, low-volume production

Support for customers that are outsourcing processes due to reduced output, particularly whereproduction has peaked out and manufacturing equipment and space are being repurposed. Examplesinclude

1)Passenger car transmission cases: 16,000 units (8,000 sets) per month under 6-month contracts

2)Cylinder heads for straight-six diesel engines of passenger cars: 100 sets per month over one year

3)Motorcycle cylinder heads: 2,000 units per month over six months

3. Fabrication of parts and test pieces

1) Automatic transmission valve bodies: 40 units

2) Motorcycle cylinders (old model): 50 units

3)Test pieces to support customer testing of new equipment

4. Fabrication of experimental parts and prototypes

1) Full processing of V8 cylinders blocks for a racing engine

2) Full processing of an experimental CVT transmission case

3)Cutting tests for parts being considered for mass production

–

–

Equipment introduction

| Processing Facilities | ||||||||

|---|---|---|---|---|---|---|---|---|

| Machine | Spindle taper hole | Manufacturer | Model | Number | X-axis | Y-axis | Z-axis | Number of ATCs |

| Horizontal machining center | 50 | ENSHU Limited | JE80 | 5 | 800 | 800 | 800 | 40 |

| ENSHU Limited | GE580H | 6 | 800 | 800 | 800 | 40 | ||

| Okuma Corporation | MA-600HB | 2 | 1000 | 900 | 1000 | 40 | ||

| Okuma Corporation | MA-600HBSP | 1 | 1000 | 900 | 1000 | 60 | ||

| MITSUI SEIKI KOGYO CO.,LTD. | HS5A(8-APC) | 1 | 850 | 700 | 750 | 150 | ||

| Makino Milling Machine Co., Ltd. | a81nx | 1 | 900 | 900 | 1020 | 187 | ||

| DMG MORI CO., LTD. | NH5000 | 2 | 730 | 730 | 850 | 54 | ||

| Matsuura Machinery Corporation | H.Plus-500 | 1 | 800 | 800 | 800 | 60 | ||

| JTEKT CORPORATION | FH630SX-i | 1 | 1050 | 900 | 1050 | 60 | ||

| SAKURAI LTD. | SH5A(5-axis) | 1 | 700 | 500 | 700 | 30 | ||

| SAKURAI LTD. | SH6A(5-axis) | 1 | 1000 | 1000 | 1000 | 60 | ||

| 40 | ENSHU Limited | JE60 | 1 | 600 | 600 | 630 | 40 | |

| ENSHU Limited | JE60S | 14 | 600 | 600 | 630 | 40 | ||

| ENSHU Limited | JE80S | 14 | 800 | 800 | 800 | 40 | ||

| ENSHU Limited | GE480H | 8 | 800 | 800 | 800 | 40 | ||

| ENSHU Limited | GE460H | 2 | 600 | 600 | 600 | 40 | ||

| ENSHU Limited | JE50S | 4 | 500 | 500 | 500 | 24 | ||

| Okuma Corporation | MX-40HA | 3 | 600 | 610 | 610 | 30 | ||

| Okuma Corporation | MA-40HA | 1 | 600 | 610 | 610 | 30 | ||

| Toyoda Machine Works Ltd. | FA45 | 1 | 600 | 600 | 560 | 40 | ||

| KIWA MACHINERY CO., LTD. | BH-45 | 1 | 640 | 610 | 680 | 40 | ||

| KIWA MACHINERY CO., LTD. | Triple H40 | 14 | 510 | 510 | 400 | 20 | ||

| JTEKT CORPORATION | FH400J | 1 | 600 | 560 | 630 | 60 | ||

| 30 | ENSHU Limited | GE30H | 4 | 500 | 500 | 500 | 24 | |

| ENSHU Limited | JE30S | 8 | 500 | 350 | 300 | 16 | ||

| Vertical machining center | 50 | ENSHU Limited | EV-650 | 1 | 1300 | 610 | 760 | 30 |

| ENSHU Limited | EV-530 | 3 | 820 | 530 | 510 | 30 | ||

| Okuma Corporation | MB-56VA | 2 | 1050 | 560 | 460 | 20 | ||

| Okuma Corporation | MX-45VB-R | 1 | 560 | 460 | 450 | 20 | ||

| Okuma Corporation | MB-46VBE | 2 | 760 | 460 | 460 | 20 | ||

| OKK | VM53R | 2 | 1050 | 530 | 510 | 30 | ||

| OKK | VM5Ⅲ | 1 | 820 | 510 | 510 | 20 | ||

| JTEKT CORPORATION | FV1165S | 3 | 1100 | 650 | 600 | 30 | ||

| 30 | ENSHU Limited | EV360 | 3 | 600 | 360 | 360 | 24 | |

| FANUC CORPORATION | a-D21LiB5 | 4 | 700 | 400 | 330 | 21 | ||

| Total | 120 | |||||||

| Other equipment | ||||||||

| Machine | Manufacturer | Model | Number | |||||

| NC lathe | Okuma Corporation | LB250T | 1 | |||||

| LB4000EXⅡ | 2 | |||||||

| Takisawa Machine Tool Co., Ltd. | TCN-3500L10 | 1 | ||||||

| Double head rotary milling machine | SAKURAI LTD. | 2A-860 | 2 | |||||

| 2A-1200 | 3 | |||||||

| 2B-1200 | 3 | |||||||

| 5M-1200 | 1 | |||||||

| 5H-1500 | 3 | |||||||

| Multi-axis head changing machine | SAKURAI LTD. | TURREX MHC-4HD | 5 | |||||

| Honing machine | SAKURAI LTD. | 35HV | 1 | |||||

| 45HV | 2 | |||||||

| General purpose lathe | 1 | |||||||

| General-purpose milling machine | 4 |

The Customers of PARTS DIV

- Ahresty Corporation

- AISIN AW CO.,LTD.

- KUBOTA CORPORATION

- KOFU MEIDENSHA ELECTRIC MFG. CO., LTD.

- JATCO LTD.

- SUZUKI MOTOR CORPORATION

- NIDEC CORPORATION

- HIROSHIMA ALUMINUM IND.CO.,LTD.

- HONDA MOTOR CO.,LTD.

- MITSUBISHI HEAVY INDUSTRIES, LTD.

- YAMAHA MOTOR CO.,LTD.

- YANMAR POWER TECHNOLOGY CO., LTD.

- RYOBI LIMITED